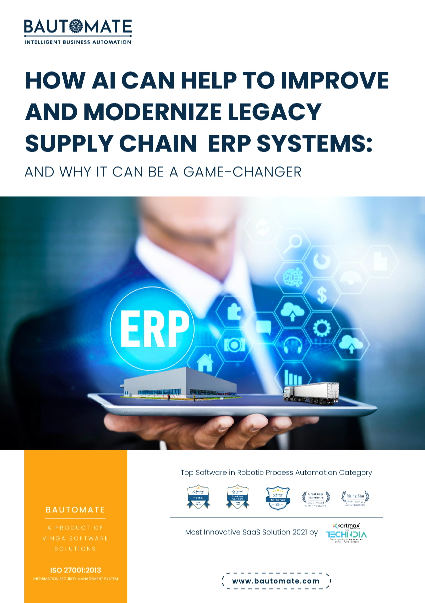

Supply chain management is the management of a product’s or service’s entire production flow, beginning with raw materials and ending with delivery to the consumer. The supply chain has never been static. Be it enterprise, medium or small, the process is the same and it comes with its own set of challenges with ever changing market demand, competition, technology and supply.

During the pandemic, the supply chain took a big hit to cope with the manufacturing demand with a shortage of supply from semiconductor industries, which were considered to be far advanced in terms of technology and the use of legacy systems/technology really challenged their effectiveness and stigma, making many not move to modern technology. But the pandemic changed the status quo.

Some of the main reasons why the supply chain was suffering were a lack of real-time data visibility. It doesn’t mean they had no system in place. Supply chain processes had sophisticated ERPs in the market to manage the supply chain process right from raw materials to delivering the end product, but most of them were human centric. ERP systems must have had options or features to adjust to the cascading effect, but it was not preempted. Most ERP systems take an approach of one solution that fits all sizes, irrespective of whether it is small, medium, or enterprise.

The legacy ERP systems come with steep learning curves, in-house skills required to handle large teams, and external production and development teams to manage change. These factors create a dependency on the OEM supplying these systems to the companies.

However, new technological platforms, such as those with low-code/no-code architecture or built on free-form code like Python, enable users to tailor what they need in their supply chains via applications that use tools like artificial intelligence (AI) and machine learning (ML). as well as natural language processing (NLP) They also don’t necessitate large development and support teams: a small group of developers and users can implement changes as needed.

These platforms enable businesses to quickly realize returns on investment (ROI), execute on strategy, and change approaches as events or the market dictate.

The legacy ERP systems come with steep learning curves, in-house skills required to handle large teams, and external production and development teams to manage change. These factors create a dependency on the OEM supplying these systems to the companies.

However, new technological platforms, such as those with low-code/no-code architecture or built on free-form code like Python, enable users to tailor what they need in their supply chains via applications that use tools like artificial intelligence (AI) and machine learning (ML). as well as natural language processing (NLP) They also don’t necessitate large development and support teams: a small group of developers and users can implement changes as needed.

These platforms enable businesses to quickly realize returns on investment (ROI), execute on strategy, and change approaches as events or the market dictate.

Key enablers that help companies take decisions on such platforms include

- A no-code or low-code environment.

- Environment for visual modeling with drag-and-drop components

- Modeler of broad workflow processes

- Integrators of multiple systems and deployments

- Scalability and adaptability

- Adaptable to the situation.

- There are no third-party dependencies.

- Pricing is based on demand.

- Human-in-the-loop

- No highly skilled resources

- Cloud hosting (SaaS)

Quick benefits of SaaS (Solution hosted on the cloud):

Almost all offline software solutions and services are now available online thanks to SaaS.

Benefits for the Customer

- Minimizing costs

- Hassle-free upgrade

- Easy Accessibility

- Collaborative work made easier

- Up-To-Date features

- Quick benefits

- Higher adoption

- Minimizes troubleshooting

The top benefits of adopting AI-powered solutions

Time to market

Today’s supply chain is tied to tight schedules, and they don’t have room to change the entire system. It will impact everything from procurement to delivery. At the same time, organizations don’t have the luxury of having a multi-year strategy to address current needs.

With a new low-code/no code framework built using AI/ML, we can reduce the implementation time from months to a few weeks or even days. The best approach to addressing this issue is by identifying the labor-intensive processes within the existing system and automating them using intelligent Business Process Automation (iBPA) with cognitive dashboards and reports, Optical Character Recognition (OCR), RPA and much more.

This implementation is unlike traditional implementations where it takes years to stabilize the implementation with robust development and deployment teams. This is a disruptive model, helping everyone in the ecosystem to scale-at-large. It helps in leveraging quick wins with added productivity and efficiency.

Competitive edge

Traditional ERP systems hamper the scalability and flexibility required as they employ off-the-shelf features that are embedded in the solution. Any improvements need to be updated on a large scale for a longer duration.

A strong strategy must be in place to identify labor-intensive processes that are critical to the functional departments and the organization. A roadmap is key to success in implementing and complementing the existing system.

Scalability & Flexibility

New technologies provide flexibility on the go with seamless integration within the existing ecosystem. Automating processes can help reduce manual errors, improve quality, productivity, efficiency, and realize quick ROI.

A goal-focused approach will help with successful implementation of automation, including defining business goals by function in the ever-demanding supply chain. Key factors include:

- Understanding the existing system

- Identify areas where automation can be done.

- Identify areas to unify all systems in an organization.

- Find champions for change.

- Monitor and measure

- Take a data-driven approach.

- Identify low, medium and high priorities.

- Maintenance and support

Be part of a new era in the digital world. Sign up for a free demo now!